Series Q Single Side Polishing and Grinding Machine for Precision Parts and Components

KIZI provides the most efficient and reliable solutions for flat lapping and polishing of components utilized in medical

Description

Basic Info.

| Model NO. | KD24QX-4 |

| Automatic Grade | Semiautomatic |

| Precision | High Precision |

| Certification | ISO 9001 |

| Condition | New |

| Power | 2.5kw |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Weight | 1040kg |

| Voltage | 380V |

| Max. Grinding Diameter | 215mm |

| Transport Package | Standard Export Packing |

| Specification | 1330*1990*2000mm |

| Trademark | KIZI |

| Origin | China |

| Production Capacity | 5 Sets/Month |

Product Description

KIZI provides the most efficient and reliable solutions for flat lapping and polishing of components utilized in medical, mechanical seals, ceramic,automotive optical,photonic,MEMS,wafer and compound semi-conductor applications and other industrial markets.Product Show

Series Q High Precision Single Side Polishing and Grinding Machine for Precision Parts and ComponentsUsage:This machine is engineered for large batch flat lapping or polishing of metal and non-metal materials, especially for stainless steel, copper, aluminum alloy, hardware components, some sealing elements of air pressure and hydraulic pressure, optical crystal, sapphire glass, LED sapphire substrate, LGP model, piezoelectric ceramics, alumina ceramics, plastic sheet and silicon chips.

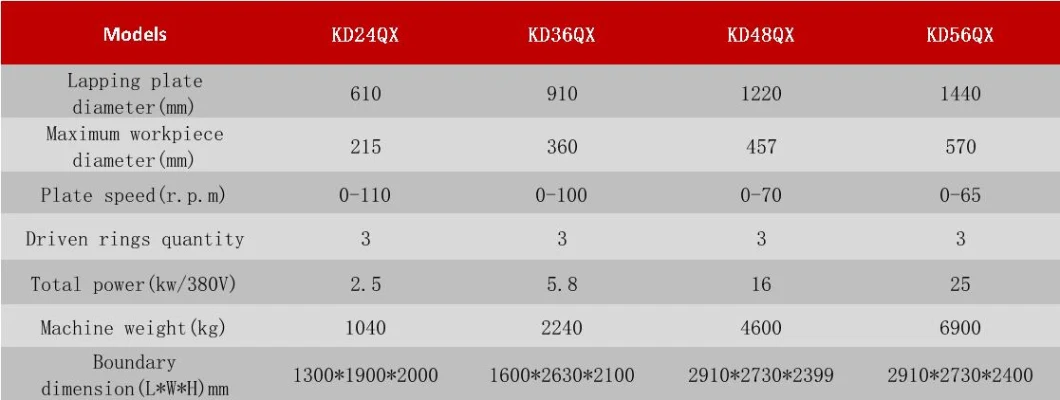

Detailed Product Data

Processing Cases

Features

1. Pneumatic pressure lifting device reduces the workload while improving work efficiency.2. Frequency conversion control achieves soft start and stop, low impact and high stability and reliability.3. Fine adjustment hoisting appliance of working table makes it easy and efficient for placing and taking workpieces.5. Equipped with high precision disc repairer machine, it could reach plate flatness of 0.002mm and ensure stability during the processing of high-precision surface as well as save a lot of time.6. Equipped with automatic slurry dosing devices, it makes the most of the slurry, reduces slurry waste and saves consumables cost while meeting environmental requirement. 7. The use of Japanese "NSK" shafting, Japanese "SMC" pneumatic components, maintenance-free power plant of Japanese "Sumitomo" and Swiss "ABB" electrical components ensures long- lasting stability, precision and durability of machine tool.

Patents

Company Show

Exhibitions

Our Service1. Factory with competative price,high quality and stability .2. R&D Dep. with 20 technicians, 5 of them in decades experience .3. Free charge of customer sample making .4. Completed After sales service and expertise support from Taiwan.Packing & DeliveryPacking Details : Packing, 1 pcs/carton.Delivery Details : Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity

Q: Do you provide samples ? is it free or extra ?

A:No, we could not offer the machine sample for free charge but can provide free proofing for the customer.

Prev: Industrial Polishing Grinder Finisher Grinding Vibratory Deburring Machine China

Next: Diamond Saw Blade Cutting Wheel 9 Inch for Granite Stone Cutting Disc with T

Our Contact

Send now